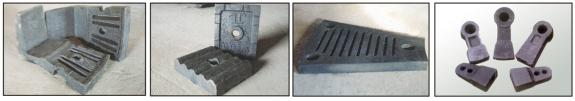

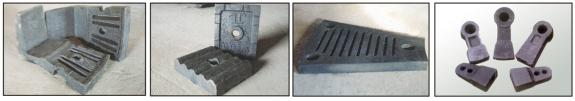

Cast steel spare part product mill liner plates is to protect the cylinder of a direct hit from grinding medium and material and friction, also can use a different form of lining board to adjust the grinding body motion, to increase grinding medium for material crushing effect, helps to improve the efficiency of the grinding mill, increase production, reduce consumption of metal.

Ball mill lining board domestic gradually replaced by alloy steel plate in the high manganese steel, but as of steel plate in the continuous application of ball mill liner, has gradually replaced the manganese steel and other lining board to become the mainstream market development.

Cylinder liner in addition to protect the body, also have an impact on the movement of grinding medium, in order to adapt to different working condition (grinding and fine grinding), the shape of the lining material is also different. When it is smash, We have strong request that the lining surface grinding body ability is stronger,at the same time the lining should have good impact resistance, When is given priority to fine grinding, lining board is relatively small, the recommended grinding body function is weak, the impact is small, and the grinding effect is stronger, lining board has good wear resistance.