1. Overview: What Are Caustic Soda Flakes and Pearls?

Same Chemical Composition

Caustic soda flakes and caustic soda pearls are both sodium hydroxide (NaOH), commonly known as caustic soda or lye. They share identical chemical properties with strong alkalinity.

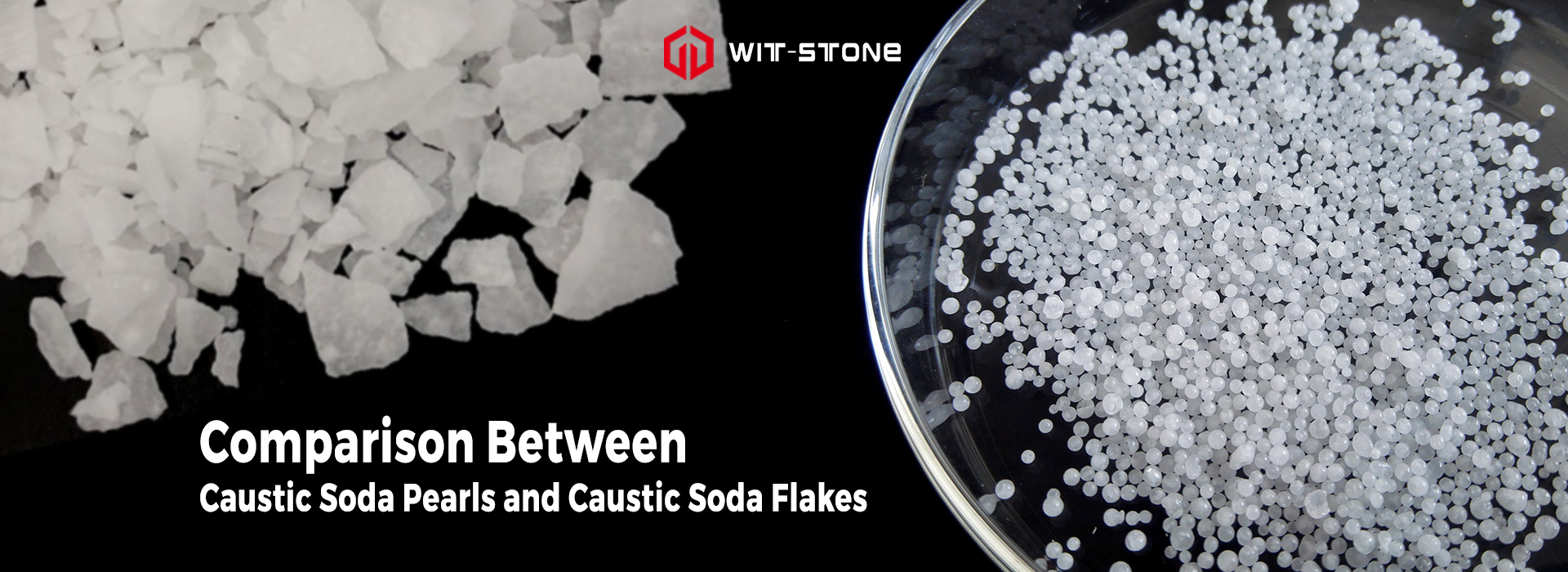

Different Physical Forms

• Caustic Soda Flakes: White, opaque, thin or flake-like pieces with irregular sizes.

• Caustic Soda Pearls: Small, uniform spherical granules, similar in size to fish eggs or caviar.

These physical differences result in significant variation in terms of packaging, handling, dissolution, and metering.

2. Solubility and Handling Performance Comparison

• Dissolution Speed:

Caustic soda pearls dissolve more easily and release heat faster due to their higher surface area-to-volume ratio and uniform particle size.

• Precision in Metering:

The uniformity of pearls makes them ideal for precise measurement and automatic feeding systems, minimizing errors. In contrast, flakes vary in size and may clog equipment.

• Packaging & Transportation:

With better flowability and fewer voids, pearls allow for more efficient packing and lower

3. Application Comparison

Common Applications of Caustic Soda Flakes

Due to traditional supply chains and lower cost, flakes are widely used in paper manufacturing, soap and detergent production, textile treatment, petroleum refining, metal surface treatment, and glass production.

Advantages and Expanded Applications of Caustic Soda Pearls

Precision and Emerging Industries

• Water Treatment: Pearls suit particle-dosing systems, enabling high accuracy in titration and continuous feeding.

• Laboratory & Reagent-Grade Use: Ideal for repackaging and small-scale lab use. Pearls dissolve evenly and allow precise standard solution preparation.

• Electronic Chemistry: In applications like photolithography and PCB etching, precise alkali concentration control is essential. Pearls integrate better with automated systems.

Food and Medical Cleaning

The small size, dissolvability, and hygienic control of pearls make them suitable for cleaning empty cans and containers. They can also be used to produce food-grade lye solutions.

Industrial Automation

Modern automated systems require consistent feeding. Pearls avoid clogging in screw feeders and pneumatic conveyors, which is often a problem with flakes.

New Energy & Environmental Fields

• Flue Gas Desulfurization: Pearls dissolve rapidly to produce alkali absorbents that efficiently remove SO₂/NOx.

• Battery Recycling: Used in film stripping and metal precipitation processes with greater ease and reduced complexity.

Other Innovative Uses

• Surface Treatment & Electroplating: Combined with automatic reactors, pearls allow accurate alkali control for better coating adhesion.

• Petrochemicals: In processes involving micro-dosing of alkali, such as desulfurization and deacidification, pearls offer faster system response.

4. Cost Efficiency and Environmental Impact

| Category | Caustic Soda Flakes | Caustic Soda Pearls |

|---|---|---|

| Production Cost | Lower due to mature processes | Slightly higher due to extra granulation steps |

| Packaging Efficiency | More void space, less volume use | Tightly packed, cost-efficient |

| Automation Compatibility | Requires crushing or grinding | Direct use, reduced equipment costs |

| Environmental Impact | More dust, messy during handling | Less dust, cleaner work environment |

Overall, caustic soda pearls offer clear advantages in automation, environmental protection, and precision, which often offset their slightly higher cost through savings in downstream handling and equipment.

5. Quality Standards and Safety Tips

• Content and Purity: Both flakes and pearls generally contain 96–99% NaOH. Selection should be based on standards like GB209-2006.

• Packaging and Storage: Keep dry and protect from CO₂ and SO₂ exposure. Common packaging includes composite bags or ton bags. Pearls are more suitable for sealed storage to maintain stability.

• Protection Measures: Always wear chemical-resistant gloves, goggles, and protective clothing. In case of contact, rinse immediately with plenty of water.

6. Market Trends and Application Outlook

With increasing industrial automation and tightening environmental regulations, caustic soda pearls are gaining popularity due to their ease of use, minimal pollution, and controllability. In the future, pearls and flakes are likely to coexist in differentiated market segments, offering complementary value.

7. Conclusion

• Physical Form is the Key Difference: Flakes are scaly and irregular, while pearls are uniform spheres, resulting in vastly different handling and application processes.

• Same Chemistry, Different Convenience: Both share the same chemical properties, but pearls dissolve faster and are better suited for automation, while flakes have a cost advantage.

• Different Application Focus: Pearls shine in labs, electronics, food, and environmental sectors; flakes remain dominant in traditional industries like papermaking and textiles.

• Tailored Export Strategies: Customize your product offerings and packaging based on client needs, considering price, total cost of ownership, and technical support.

You can place an order or ask any questions, please feel free to contact at feronia@wit-stone.com | +86-15655559799

Post time: Jul-03-2025